Welding

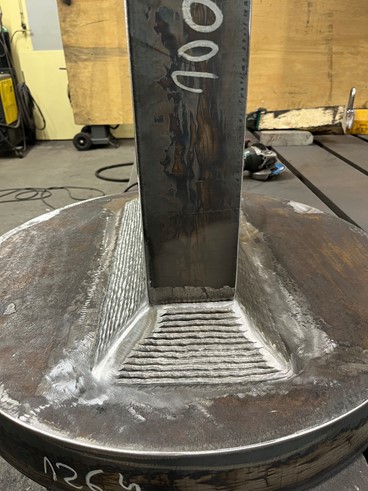

Welding with a focus on quality and world class craftsmanship in steel constructions

Welding in uniform quality

Do you request welding in steel, stainless steel and aluminum that meets the highest demands of the industry? In BSB Industry, we are specialists and certified in all common welding processes. We deliver welding craftsmanship of the highest quality.

Get a quote for welding tasksWhy choose BSB Industry?

- You get a partner that is certified in all common welding processes

- Your products are welded with focus on quality and durability

- You can perform NDT quality control according to your wishes

- MIG, MAG and TIG Welding

- Your products meet the strictest requirements in the industry

- You get a high-capacity partner

Large capacity and high degree of flexibility

We have 20,000 square meters under roof at our plants in Denmark and Poland. With our high capacity and high degree of flexibility, your company gets quality welding of both larger and smaller components at competitive prices. Naturally delivered within the agreed time.

MIG and MAG welding (131, 135, 136, 138)

In the iron and metal industry, MIG and MAG welding are the most widely used welding methods. In BSB Industry, we naturally master both welding methods, and our skilled employees are ready to help you and your company accomplish all your welding tasks.

As you may know, MIG and MAG welding are welding methods where the welding wire is continuously added during welding. In welding, we use different welding materials, shielding gases and electric currents in the welding machine. This means that we can weld in all weldable materials with MIG and MAG welding.

Customer case: Airco DIET

"The BSB Industry organization applied all its skills to this project. They have cut, welded and bent an approximate 25 tons of steel as well as having been responsible for project management, procurement and coordination. We have felt very secure and confident in the final outcome. The dialogue has been solution-oriented, and together we have succeeded in optimizing the work process, so that we have been able to reach the target on time."

Project Engineer at Airco DIET

Ronni Blicher Madsen

TIG welding stainless (141)

In BSB Industry, we have extensive experience with MIG and MAG welding in ordinary steel and stainless steel. If you need to get welded in thinner, more precious materials such as stainless steel and aluminum, we typically use TIG welding.

TIG welding is suitable for finer workpieces, because with this welding method we can get a high-quality welding that requires only minimum finishing.

Which welding method best suits your solution is decided based on material and requirements for appearance. Our focus is of course on securing for you the best result and the most cost-effective solution.

In BSB Industry we are certified according to DS / EN 3834-2.

Get a quote for welded constructionsCertifications are your guarantee of quality

At BSB Industry, we produce quality solutions that meet the requirements of leading industrial customers. We are naturally ISO 9001 certified, as well as certified in all common welding processes. We continuously work on quality assurance and internal NDT control. This results in products that match the requirements your company has for quality, tolerance levels, and delivery times.

Make use of our professional expertise

In BSB Industry you can have welding work done by order or you can use our professional consulting and experience to prepare for production or develop your products. If you request NDT quality control, we will test according to your wishes and needs.

The satisfaction of our customers reflects that we are a supplier to a wide range of companies in the wind industry and traditional industry. Our three factories with state-of-the-art machinery and skilled work force handle all tasks, whether you require the manufacturing of individual units or complete total solutions in steel, stainless steel and aluminum.

Are you in need of welding?

Get welding of steel, stainless steel and aluminum that meet the industry's highest demands.

Contact us

FAQ Welding

Get answers to some of our most frequently asked questions about welding and welded constructions.

The price of welding and welded constructions depends on the scope of the task. We weld in steel types from S235JR up to S690QL. The choice of steel type and our time consumption on the task affects the price. Price is available upon request.

At BSB Industry, we have nearly 100 certified welders available to execute your order, employed in Denmark and Poland. We offer high capacity and fast delivery times. However, the delivery time will always depend on the specific order, and there is, of course, a difference whether you need to have a larger, complex series produced or just a single item.

We weld in aluminum, steel, and stainless steel.

We use MIG, MAG, and TIG welding methods.

131: MIG Welding in aluminum

135: MAG Welding with solid wire - also known as CO2 weldin

136: MAG Tubular wire welding

138: MAG Metal cored tubular wire welding

141: TIG Welding in stainless steel, steel, and aluminum

Yes, based on Welding Procedure Qualification Reports (WPQR), we develop Welding Procedure Specifications (WPS) for all welding procedures that we qualify according to DS/EN ISO 15614.

The work results in a heat input and a "recipe" for which wire and gas to use, and at what amperage and speed the welding work should be performed. With WPS, we meet the wind industry's strictest requirements for welding procedures.

At BSB Industry, we have a range of certifications, and additionally, we work according to specific customer requirements for parts of other standards. We are always open to individual customer requirements. Currently, we are certified according to:

- DS/EN 3834-2

- EN1090-1 + A1 2011 Alu

- EN1090-1 + A1 2011 Steel

- EN1090-2

- EN 1090-EXC3

- ISO 9001

- ISO 45001

- ISO 14001

Yes, all our welders in both Denmark and Poland are certified according to ISO 9606-1 and ISO 9606-2.

We always work according to agreement with the customer and according to Welding Procedure Specification (WPS). In combination with our process control, certifications, well-trained welders, and always calibrated equipment, it is the foundation for our high, consistent quality of welded constructions.

We have internal NDT control with Visual Testing (VT), Magnetic Testing (MT), Penetrant Testing (PT), and Ultrasonic Testing (UT).

Yes, we have full traceability and deliver according to the customer's wishes regarding labeling, tracking, and documentation. We can always refer to a 3.1 material certificate, and in the traceability list, we can document which heat number the item comes from and which plate it is cut from.

Yes, we continuously invest in welding robots and use them, among other things, in processes where we have unilaterally wearing repetitive manual work, which helps improve the working environment at BSB Industry.

Our investments in welding robots increase our capacity and make us competitive in terms of price, quality, and delivery reliability for serial orders.

BSB Industry is deeply committed to sustainability and ESG. In welding, we are the first in Denmark and the second in the Nordic region to start using green, climate-friendly, and CO2-neutral cutting and welding gases, which emits a lower CO2 footprint in our green energy account.

Moneywise, the CO2-neutral product series is about 7 percent more expensive for us. We have chosen, though, to bear that expense because we believe that as a company in the heavy industry, we have a particular responsibility to make a climate effort and reduce our CO2 emissions.

How does a cutting and welding gas become CO2-neutral?

In the production and transportation of the CO2-neutral cutting and welding gases, renewable energy and green fuel are used, while a small part is climate-compensated through certified afforestation projects.

The health, safety, and well-being of our employees are our top priority. In connection with welding in both Denmark and Poland, we always use fresh air masks with activated carbon filters, and of course, we have exhaust ventilation and provide all necessary equipment for the welders.