Robots can address recruitment challenges

Like their counterparts in the market, BSB Industry struggles to recruit the number of welders needed to keep up with production.

- Qualified welders are in really short supply, and even though we're willing to invest in upskilling our employees, it turns out to not be enough. This is where welding robots come to our rescue, as they can boost our productive capacity in the department, Heino Pedersen explains, highlighting another significant benefit of investing in welding robots.

Welders need to upskill

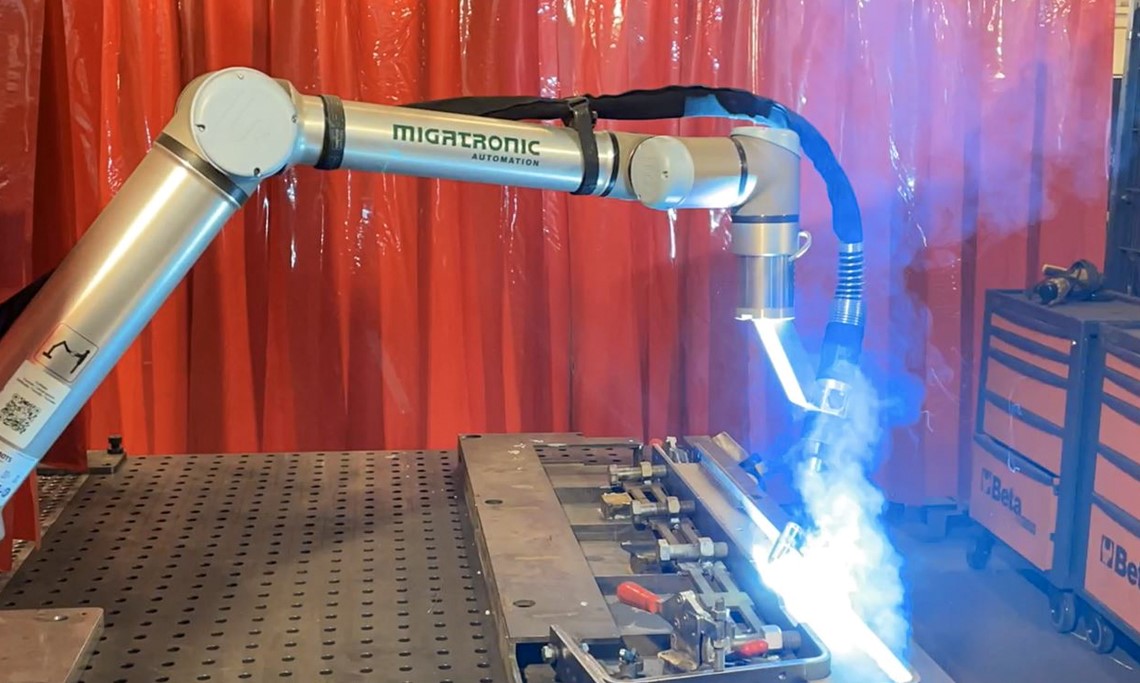

Welding robots will undoubtedly take on more tasks in the future because they are efficient and deliver high, consistent quality.

- Our investments in welding robots increase our capacity and make us more competitive in terms of price, quality, and delivery reliability. These are important factors that help ensure that we will continue to be an attractive partner for our customers and win large-quantity production orders in a highly competitive market, explains Heino Pedersen.

He puts emphasis on the point that without skilled employees, robots are worthless.

- We will still need skilled employees to prepare the work and "feed" the robots, just as we are already working on upskilling employees who can, will, and have ambitions to program and build fixtures for the welding robots. With the advent of welding robots, new exciting opportunities arise for our employees, and we will do everything to upskill our current workforce instead of just recruiting new employees, emphasizes Heino Pedersen.